This is the first in an occasional series in which I’ll improve an existing job aid and explain the reasons for the changes.

The original

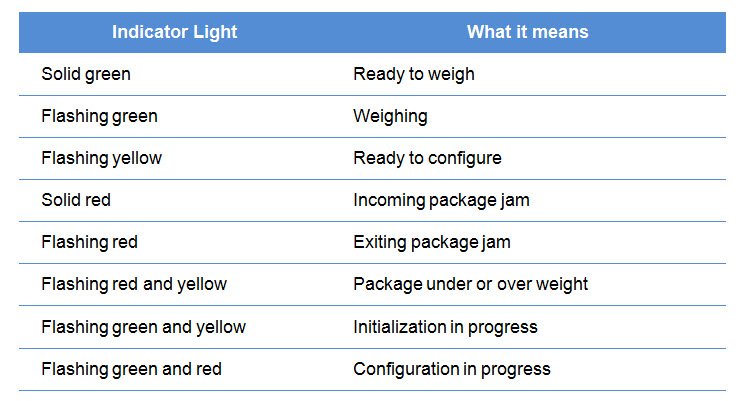

This is a fictionalized version of a table found in a user manual for some electronic equipment. I’ve changed details to refer to the (imaginary) MacLellan Weight Monitor, a type of checkweigher. The Weight Monitor checks the weight of boxes of pharmaceuticals on a packaging line. (I’ve put some background at the end of this post, but it’s not essential to the job aid makeover.)

This is a fictionalized version of a table found in a user manual for some electronic equipment. I’ve changed details to refer to the (imaginary) MacLellan Weight Monitor, a type of checkweigher. The Weight Monitor checks the weight of boxes of pharmaceuticals on a packaging line. (I’ve put some background at the end of this post, but it’s not essential to the job aid makeover.)

The original job aid is a reference to show various statuses that the Weight Monitor can have, as well as the indicator lights that display for each status. I’ve rewritten some of the statuses here, but the language of the original is similar.

Weak points

What’s wrong with the original?

Purpose: What’s the table for?

A technician might say “it tells you what status the different lights represent,” but the way it’s set up, it really tell you “if the status is X, then the lights will be Y.” On the job, the user can already see the lights; he wants to know what they mean.

Language: It’s not obvious from the table, but the typical user will not be familiar with terms like initialization, configuration, to say nothing of parameter failure. Too many engineers, not enough packaging line operators.

Title: not helpful. As is, could just as well be left off.

Organization: How is this table organized? Not by sequence, not by frequency, not alphabetical by status, and not alphabetical by color.

The makeover

What and why

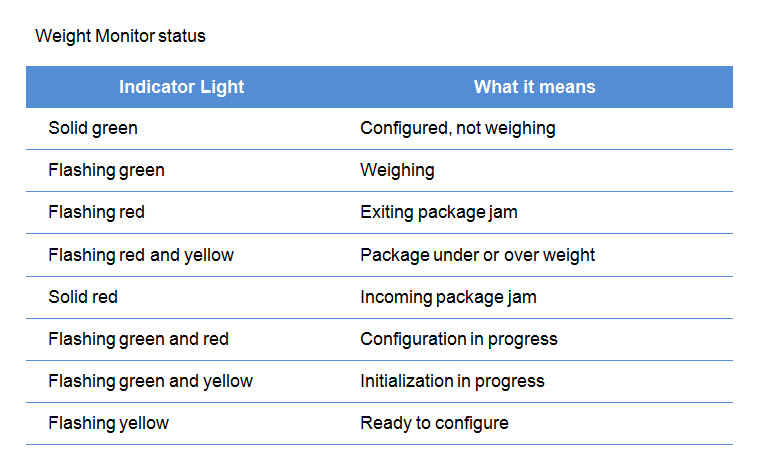

Purpose: explain what the Weight Monitor’s lights mean.

The new version shows the when/then principle in action: start with what the worker sees or receives or experiences — in this case, the colors of the lights. So colors go on the left: “WHEN the light is flashing red…”

Once you have the color, you move to the meaning: “THEN there’s a jam where the packages exit the Weight Monitor.”

In the original version, the layout was backwards: the left column showed meanings, and I had to skim each one and check its color in order to figure out what a flashing red light meant.

Language

Starting with “device status,” which is now “what it means,” I’ve rewritten several items to be clearer from the worker’s point of view. “Parameter failure” was the engineering way to say that a package didn’t fail within the minimum / maximum weight range. Either way, the Weight Monitor will bump the package off the line and flash red and yellow lights. “Package over or under weight” is clearer.

Title

As simple as it seems, “Weight Monitor status” sets the table in context. What the engineers called indicator lights are meant to show the status of the machine in the workplace.

…As for organization, this first draft has the same order (or lack of order) as the original. I can see a number of ways to arrange the rows, such as by sequence in the process. But in a second pass, I went with color:

Makeover, version two

There are a lot of colors here. I decided to put the single colors first, in green-yellow-red order, followed by the combinations. In the case of those multi-color states, “flashing red and yellow,” like most of the items above it, relates to the operation of the packaging line. The last two combinations are one-time indicators that you’d see when you started the device up (initialization) and once you’d entered the programming for the specific item you were packaging (configuration).

Background on the Weight Monitor:

As part of the packaging process, Dosage Pharmaceutical programs the Weight Monitor with an acceptable weight range for one packaging unit. For example, when the line is packaging physician samples for 200-milligram doses of Nullaproxin, the package unit is one carton, and the weight is based on:

– The carton itself, its label, and its seal

– An eight-page information package for the physician

– 24 wallets (the medication sample package given to a patient)

Each wallet is made up of a cardboard case, 14 plastic blisters (thermoplastic bubbles and foil backing), one tablet per blister, and an information sheet for the patient.

Each carton moves onto the Weight Monitor. If the carton is too light or too heavy, based on the configuration for the specific product, the Weight Monitor bumps the package into a bin for a worker to determine and remedy the problem.